How it works

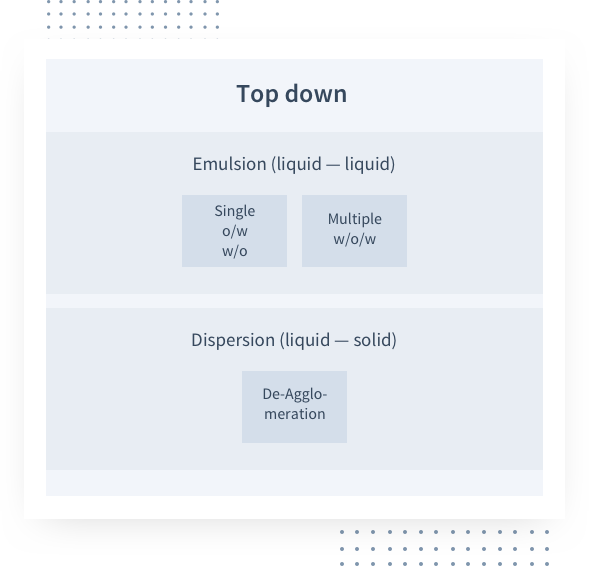

State-of-the-art nanoparticle manufacturing (such as in colloidal mills) involves a top-down process, where nanoparticles are made from large-particle powders through mechanical force.

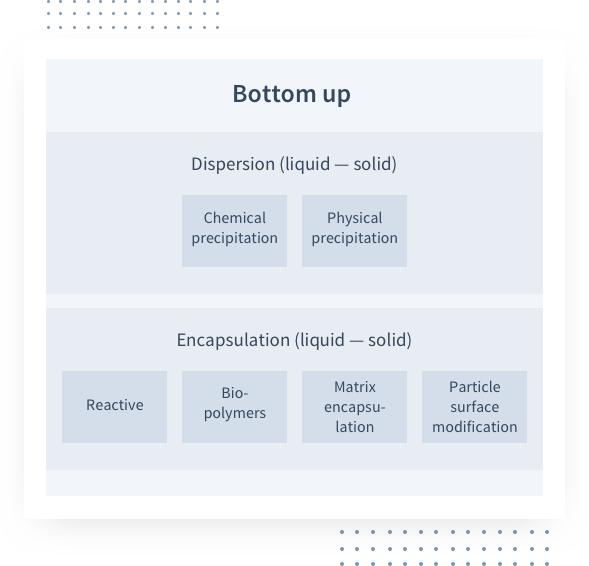

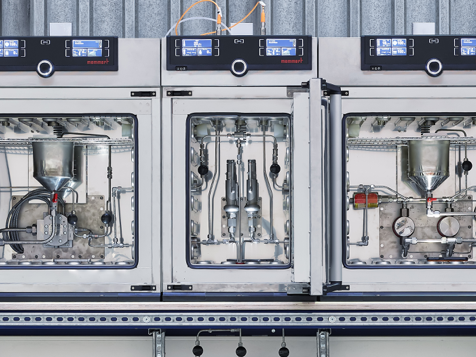

In contrast, our MJR® Technology uses a bottom-up process in which nanoparticles and microparticles (< 1 µm) are produced from dissolved molecules by means of precipitation.

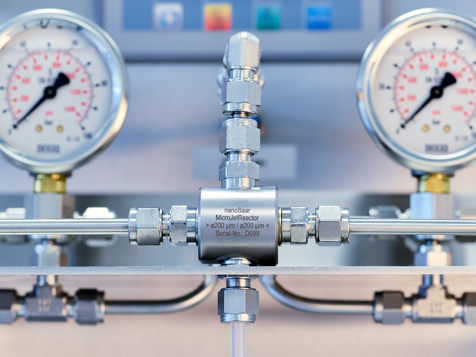

The 3 cm-long reactor has four openings and contains a central mixing chamber where the synthesis occurs.